PU-PIR (Polyurethane-Polyisocyanurate) sandwich panels are widely used in the construction industry due to their high insulation, durability and versatility. These panels are made by sandwiching a core of insulation material between two sheets of metal or other materials. The production of these panels requires specialized machinery that can precisely control the process of mixing and pouring the foam, as well as accurately cutting and shaping the panel to desired size.

The PU-PIR sandwich panel production machine is a complex and sophisticated machine that is designed to produce panels of consistent quality and precise dimensions. The machine typically consists of several main components, including a mixing and pouring unit, a cutting unit, and a pressing unit.

The mixing and pouring unit is responsible for mixing the PU-PIR foam material and dispensing it into the panel mold. This unit is equipped with precision pumps and mixers that accurately control the flow rate and mixing of the material. The cutting unit is responsible for cutting the panels to the desired size and shape, using high-precision saws and cutting tools. The pressing unit is responsible for applying pressure to the panels to ensure a consistent and uniform panel density.

The PU-PIR sandwich panel production machine is operated by trained technicians who monitor the machine’s performance and make any necessary adjustments to ensure the panels are produced to the desired specifications. The machine is also equipped with advanced control systems that allow for remote monitoring and control of the production process, ensuring consistent and efficient operation.

In conclusion, the PU-PIR sandwich panel production machine is an essential tool in the production of high-quality PU-PIR panels. With its precise and consistent operation, it enables the production of panels that meet exacting standards and provide reliable and efficient insulation solutions for a wide range of construction applications.

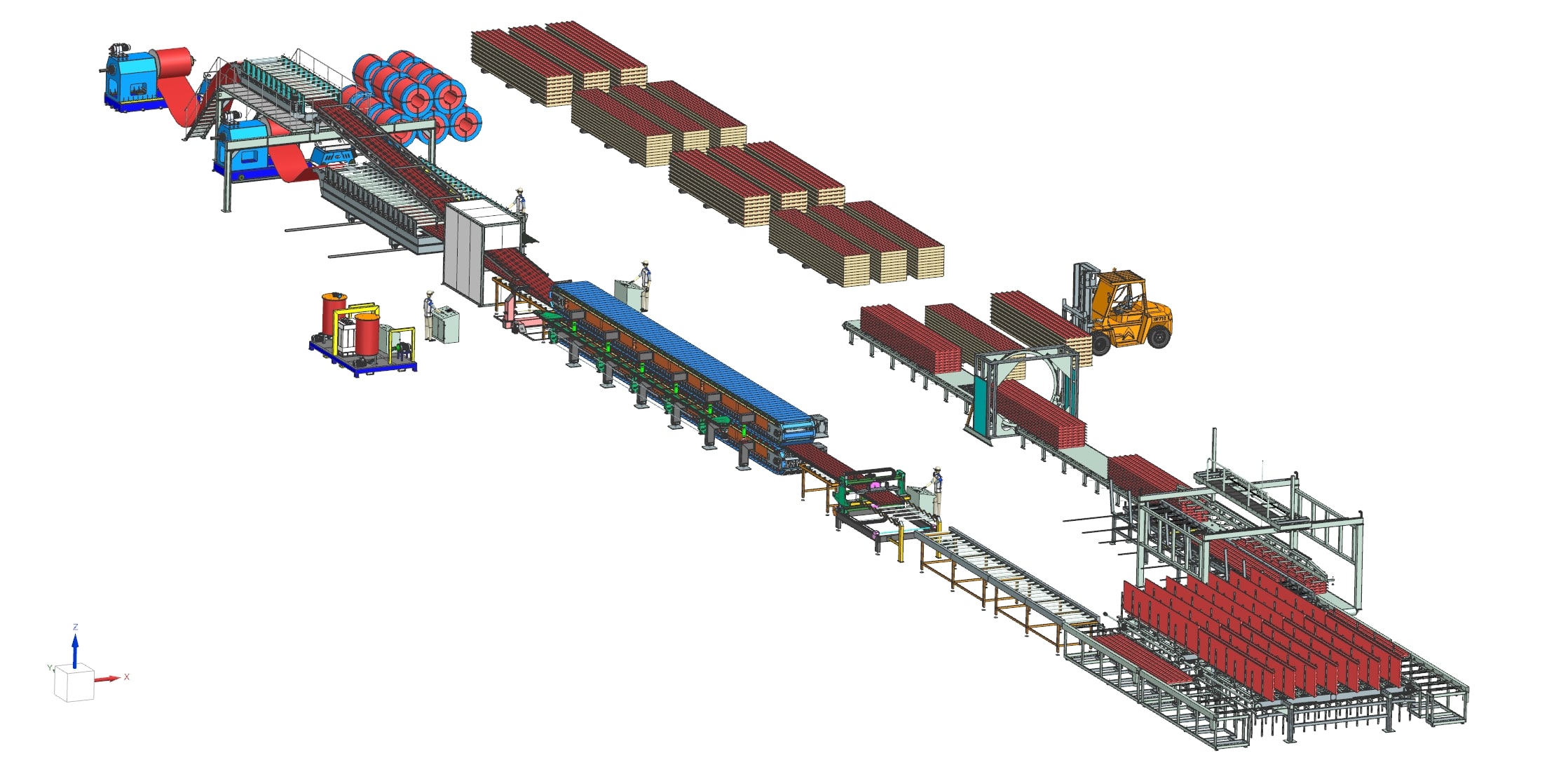

FLOW CHART

Uncoiler – Feeding Guide – Protective Film Coating – Roll Forming Machine – Rolling Conveyer – Steel Pre-Heating – Foaming Machine – Double Belt Pressing Machine – Rolling Conveyer – Auto Fly Cutting To Length – Runout Table – Auto Vacuum Stacker – Auto Packing Machine

Sandwich panels have a composite structure whose core can be filled up with insulation materials, such as polyurethane foam or rock wool. These panels are widely used in the building industry.

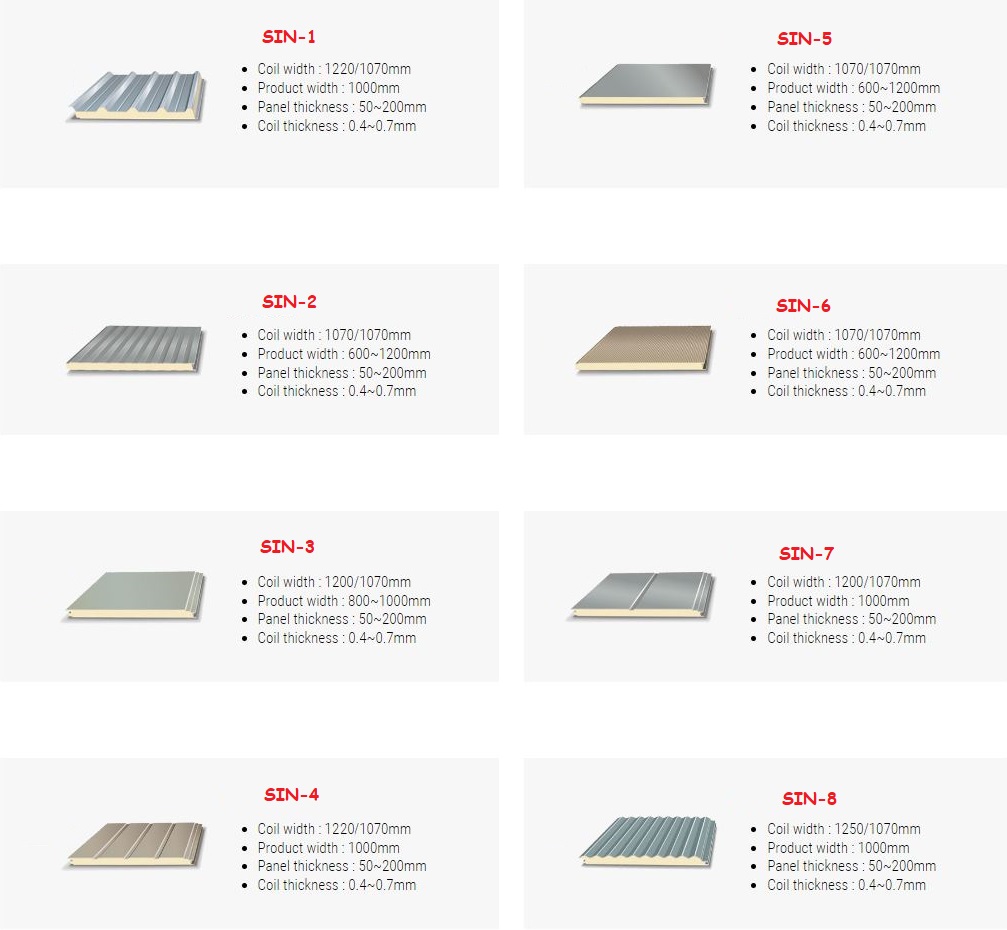

Our equipment is capable of non-stop manufacturing, thus ensuring a constant level of production. Additionally, Sinus Machine produces panels in all shapes and sizes. Long-term performance is the result of a careful selection of the best materials. Please, feel free to contact us for an estimate or for any further information about sandwich panel production lines.

Example sandwich panel lines we have made

Revolutionizing the Construction Industry with Sandwich Panel Production Lines

The construction industry is constantly evolving, and keeping up with the latest technology and innovations is crucial for staying ahead of the competition. One such innovation is the use of sandwich panels in building construction, and the production line for these panels is becoming increasingly popular among builders and contractors.

A sandwich panel is made up of two layers of metal sheets, with an insulation material in between. This combination results in a strong, durable, and lightweight material that is perfect for use in construction. The panels are widely used in walls, roofs, and floors, and offer numerous benefits over traditional building materials.

The production line for sandwich panels is a highly automated process that ensures consistent quality and efficiency. The production process starts with the preparation of the metal sheets, which are then fed into the machine. The insulation material is added next, and the two metal sheets are combined to form the panel. The final step involves cutting the panel to the required size, ready for use on the construction site.

Investing in a sandwich panel production line is a smart move for any company looking to expand their product range and stay ahead of the competition. The production process is fast, efficient, and produces a product that is in high demand among builders and contractors. The panels are eco-friendly, energy-efficient, and offer numerous benefits over traditional building materials, making them an attractive choice for construction projects.

In conclusion, the use of sandwich panels in construction is revolutionizing the industry, and the production line for these panels is an essential investment for any company looking to stay ahead of the competition. The panels offer numerous benefits, including strength, durability, and energy efficiency, and the production process is fast and efficient, ensuring consistent quality and affordability. Invest in a sandwich panel production line today and take your construction business to the next level.